- HTK-Vent GmbH Eisenhütte31/B A-3400 Klosterneuburg

- +43 (0) 664 467 4020

- info@htk-vent.at

This selection program is provided in cooperation with Venture Industries.

This selection program is provided in cooperation with Venture Industries.

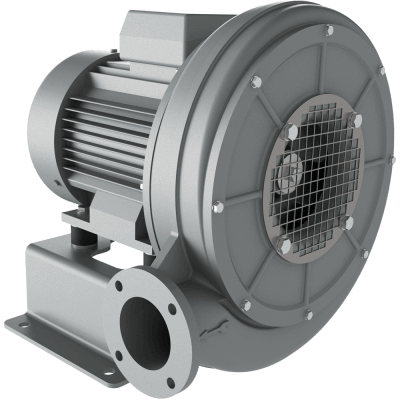

Home » Centrifugal fans » Centrifugal fan-HPB-F 200HZ

The fan is designed for transport systems of non-aggressive and non-explosive gases without pollution.

Typical uses:

The converter supplying the motor must have the following U(f) classification:

where: U – rated voltage of the motor operation; f – frequency 200Hz

If the recommendations are not followed, the motor current increases disproportionately and the motor does not reach the rated speed. Under no circumstances should the frequency (rotational speed) be set higher than the 200Hz frequency stated on the nameplate, because the motor may be overloaded or the blower damaged due to too high speed.

The so-called boost, as this causes the drive motor to heat up too much. In order to protect the motor, a temperature sensor must be connected to the appropriate inputs of the converter.

Do you have questions about our services or a specific project?

We are happy to assist you and develop solutions that will help you and your company move forward.

Please use our contact form.