Home » Air Knife Systems

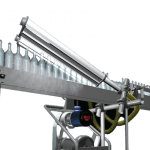

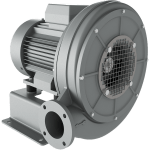

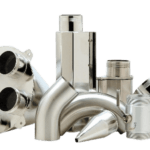

In contrast to the competition, where mostly piston compressors and jet nozzles are used, we work exclusively with compact, high-speed turbo fans, which generate a constant, laminar air flow or air curtain in a particularly efficient manner (efficiency >70%) in conjunction with specially designed nozzles.

The result is outstanding and has clear cost advantages compared to other technologies.

Efficient and customized solution for your flow needs. Constant, uniform airflow with higher efficiency than compressed air technologies. Discover the advantages now of the HTK-Vent Air Knife:

A technology that pays off

Our turbo fans in combination with specially developed nozzles generate a constant air flow with an efficiency often exceeding 70%. Compared to conventional methods, this means not only an excellent result, but also considerable cost advantages. With 90% lower energy consumption than compressed air technologies and significantly lower maintenance costs, our solutions often pay for themselves within a few months.

Individual solutions for your requirements

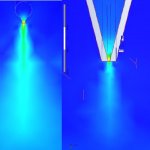

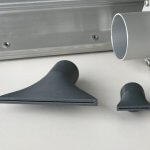

We work with CAD and 3D printing to create customized solutions for your unique airflow needs. Pre-calculated and simulated through CFD simulations, we can ensure that our solutions meet your requirements. In addition, we often test our simulation setups live at the customer’s site before integrating them into the plant.

Precise control and lower noise emissions

With our Air Knife, you can precisely control air volume and velocity, resulting in increased product quality. Line losses are also a thing of the past, as our Air Knife is installed on-site for increased plant flexibility. In addition, our systems are significantly less sensitive to changing operating conditions than compressed air systems and offer lower noise emissions.

Safety in hazardous areas

By using clean ambient air instead of compressed air, our solutions can also be used in potentially explosive atmospheres. And unlike compressed air systems, there is no wear and tear on the nozzles because they are operated by clean ambient air.

Rely on HTK-Vent’s expertise to meet your unique airflow needs. We offer an efficient, customized and safe solution for your facility.

Your advantages with HTK-Vent Air Knife:

| ALT: Compressor compressed air | NEW: Turbo fan | |

| System pressure | 6,5 bar | 0,3 bar |

| Volume flow | 1.500m³/h | 1.500m³/h |

| Drive power | 232kW Compressor | 14kW Turbo fan |

| Energy costs | EUR 4.176/Week | EUR 253/Week |

Air Knives: The clever solution for efficient production processes

Air Knives are true all-rounders when it comes to saving costs and increasing productivity. Unlike compressed air, Air Knives use clean ambient air, enabling savings of up to 90% in energy costs.

From drying to shaping – the possible applications

The possible applications of Air Knives are manifold. Products such as paper, textiles, bottles and components can be dried effectively. The removal of dust and residues from products and machines is also possible without any problems. Furthermore, products and machines can be cooled or heated and materials can be separated as in the processing of recycled materials. Air Knives also provide valuable services in the shaping of products, for example in the manufacture of food packaging.

Customized solutions by experienced technicians

Every application and plant requires an individual solution. Our experienced technicians will be happy to assist you in finding the optimum solution. By using CAD and 3D printing technology, we can offer you customized solutions. A free on-site survey enables us to prepare a written profitability calculation for you.

Benefit from the advantages of Air Knives

Convince yourself of the advantages of Air Knives and contact us today. Our experts will be happy to show you the best possible solution for your applications, enabling efficient and successful production processes.

Stationary or mobile: we test your products

Our HTK-Vent test laboratory is the solution for everyone who wants to have their products tested for their flow properties. Whether stationary in our laboratory or mobile at your site, we offer you the possibility to test the performance of your products and document it in a report.

Mobile testing, fast results

With our mobile test facility, we can work directly at your site and show you how effectively our machine works under real operating conditions. For you, this means minimal downtime and fast results.

Air knife processes and more

Our applications include various air knife processes such as drying, cooling and cleaning. We also supply fan air to air ducts to determine leakage rates. We perform moisture, sound, velocity, volume flow, pressure and temperature measurements.

Advantages HTK-Vent test laboratory

With our HTK-Vent test laboratory, we offer you a fast and efficient way to test the flow characteristics of your products. Whether mobile or stationary, our test systems provide you with accurate results and make fluid mechanics come alive.

Do you have questions about our services or a specific project?

We are happy to assist you and develop solutions that will help you and your company move forward.

Please use our contact form.

HTK-Vent GmbH

Inkustraße 1-7/Stiege 8

A-3400 Klosterneuburg

Phone: + 43 (0) 664 467 40 20

E-Mail: info@htk-vent.at

Internet: www.htk-vent.at